Radio shuttle is a semi-automated high-density storage solution for storage of goods, which uses an automatic device to move in the channel back and forth for transportation, forklift pick up at the end.

Radio shuttle racking system is suitable for high density storage with similar structure as drive in racking system using in cold storage, food and beverage industry and other low level of SKU. It could helps you to create maximum use of the storage and simplifies loading and unloading of goods.

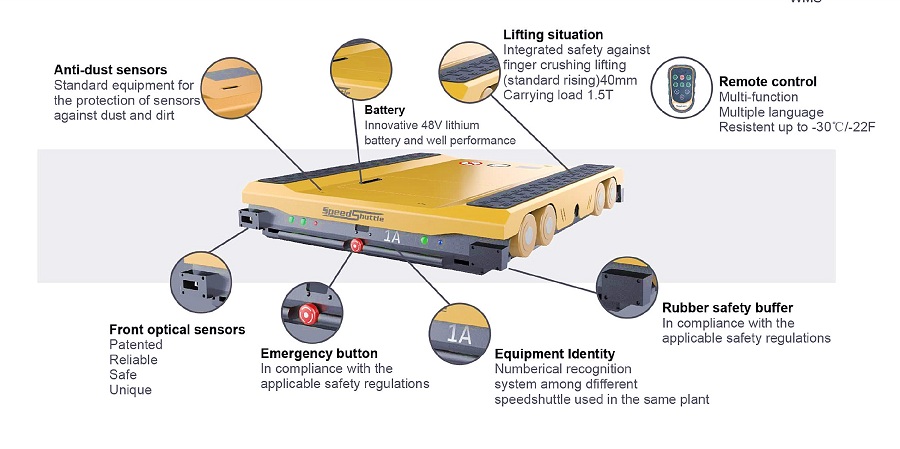

Radio pallet shuttle will automatically load and unload pallets with high efficiency, no need forklift enter into the aisle. Running speed of pallet shuttle is about 0.8-1.2m/s, maximum load 1500kg.

The radio shuttle is widely used in Food&Beverage, Cold Store, Chemical, Automobile, Logistics Center and Chemical Industry, which will highly improve work efficiency and save labor cost.

1. Lower risk of damage to the rack and operator.

2. Automatically load, unload, organize pallets with high precision, fast and sustainable.

3. Save labor cost, improve work efficiency and inventory turnover.

4. Both radio shuttle and racks are designed and produced by Maxrac team, CE testing approved.

5. Available for different size of pallets.

6. Efficient load and unload system, which ensures high accuracy.

7. Less damage to the racking units as the forklift does not enter the racking unit.

8. Greatly reduced labor cost.

9. Compatible with different pallet sizes.

10. Ideal for storage at low temperature(-25℃).

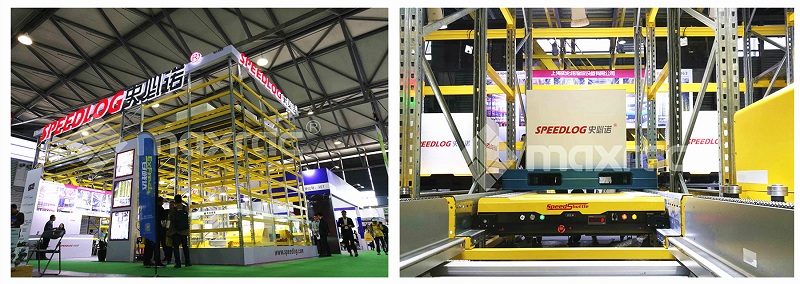

Shuttle Carrier system displayed in the CeMAT exhibition:

Shuttle carts racking solution that adapts to any warehouse — no matter the size of existing space, allowing maximum optimization of the storage volume and reducing the working times.The space utilization of warehouse from 40% up to 80% and automatic order picking efficiency doubled or tripled compared to drive in system.

Radio shuttle racking has supported WCS, WMS software and fulfilled in line with the new generation of Internet of things(IoT)plus era and realized the long-distance monitor and control (no limit of flow).By using the network solve your problem more efficiently and greatly reduce the labor cost.

In domestic and oversea market, we have completed lots of pallet shuttle racking projects for clients from different industries, such like New Zealand, Qatar, Vietnam, Serbia, Canada, etc. Radio shuttle works well with a fast and stable performance.

See related project case:

Radio shuttle rack system in Doha

Radio Pallet Shuttle Rack Specification:

| Radio Shuttle Rack Performance | |

| Traveling Speed | Loaded 1.2m/s Unloaded 0.8m/s |

| Working Range time | 8-10h |

| Weight | 250kg |

| Remote distance | 500m |

| Carrying load | 1500kg |

| Pallet size | 1m-1.2m |

| Pallet lift height | 45mm |

| Lifting and downtime | 1.5s |

| Battery | |

| Voltage | 24V |

| Capacity lithium battery | 60Ah |

| Charging period | 3 hours at room temperature(0℃-45℃)6 hours at low temperature(-25℃ -0℃) |

| Battery life | More than 2000 times |

| Remote control | |

| Frequency | 433.05MHz-434.6MHz |

| Battery | Rechargeable |

| Protection degree | IP 65 |

| Screen | LED |

| Control mode | Manual and automatic |

| Communication capacity | 8 Shuttle carts |

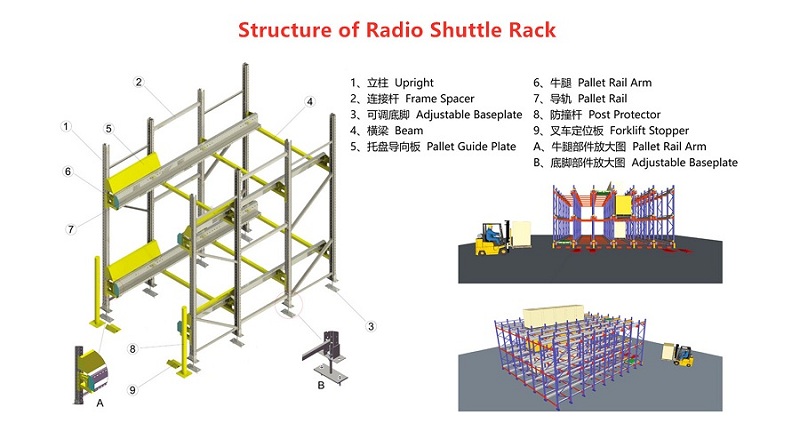

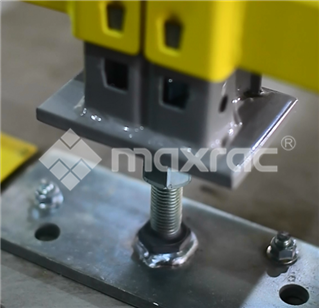

Adjustable baseplate

Adjustable baseplate  Pallet rail arm

Pallet rail arm  Upright

Upright